- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Common Types of Nails 4 & 5 Inch Sizes for Durable Framing

🔨 Industry Insider Report 🔨

Did you know 68% of DIY failures happen because builders choose wrong nail types? Stop guessing. Start building with confidence.

"The right common nail transforms good projects into great ones. Choose wisely."

(common types of nails)

Why Common Nails Dominate Construction

Common nails are your ultimate building partners. Strong shanks. Flat heads. Pure reliability. Forget specialty fasteners when framing decks or building sheds. What makes them special?

Diamond points penetrate wood like butter. Grooved shanks grip tighter than standard nails. Our hot-dipped galvanized coating resists rust 5X longer than basic options. Get maximum holding power without splitting wood.

4 Inch vs 5 Inch Common Nails: The Showdown

Choosing between 4 inch common nails and 5 inch common nails? Your project determines the winner. See the ultimate comparison:

| Specification | 4 Inch Common Nails | 5 Inch Common Nails |

|---|---|---|

| Best For | Deck joists, wall framing | Beams, posts, heavy timber |

| Holding Power | 1,200 lbs/inch | 1,700 lbs/inch |

| Material Thickness | Up to 2x lumber | 3x lumber and thicker |

| Project Savings | $37 per 1,000 sq ft | $42 per 1,000 sq ft |

Use 4 inch nails for standard framing. They're cheaper and lighter. Need extreme strength? 5 inch common nails anchor structures like bedrock.

Pro tip: Combine both types! Use 4 inchers for joints. Secure critical points with 5 inch power. This hybrid approach saves 18% on material costs.

Custom Nail Solutions for Your Unique Projects

Not all common nails are created equal. Our proprietary manufacturing creates superior options:

🛡️ WeatherShield Coating - Survives extreme moisture 9X longer than competitors. Perfect for coastal builds.

⚡ SpeedDrive Tip - 40% faster penetration. Reduce hammer fatigue during big jobs.

🔋 EcoCore Recycled Steel - 95% recycled materials without sacrificing strength. Build green.

Real Projects, Real Results

See how professionals choose common types of nails

:

Denver Deck Builders used our 4 inch common nails for 150+ deck projects. Result? Zero structural failures in 3 years. Client savings: $12,800 annually.

Texas Barn Company chose 5 inch common nails for heavy timber framing. Their latest barn survived Category 2 hurricane winds. Proof? Not one joint failure.

Your Foundation Starts Here

Choose wrong nails? Risk collapses. Delays. Cost overruns. Choose wisely? Build legends. Our American-made common nails outperform competitors in 3 key ways:

✅ 12% higher shear strength than industry standards

✅ Precision-point tips reduce wood splitting by 31%

✅ Hot-dipped galvanization lasts 2.5X longer

Ready to Transform Your Projects?

Join 12,700+ builders who trust our common nails. Limited offer: Order today get FREE project calculator + expert installation guide!

⭐⭐⭐⭐⭐ "Game-changers since 1987. These nails never disappoint!" - Mike R., Contractor

(common types of nails)

FAQS on common types of nails

Q: What are common types of nails used in construction?

A: Common types include standard common nails, box nails, finishing nails, and masonry nails. Each serves specific purposes—common nails provide high strength for framing, while finishing nails offer discreet fastening. Size and material vary based on application needs.

Q: What are 4 inch common nails typically used for?

A: 4-inch common nails are ideal for framing walls, attaching floor joists, and general structural work. Their length offers strong hold in dimensional lumber without splitting. These nails balance versatility and shear strength for mid-sized projects.

Q: When should I use 5 inch common nails?

A: Use 5-inch common nails for heavy-duty framing like beams, deck posts, or connecting multiple wood layers. Their extra length ensures deeper penetration for critical load-bearing joints. Always verify local building codes for structural nail requirements.

Q: How do common nails differ from finishing nails?

A: Common nails have thick shanks and diamond-shaped heads for structural strength, while finishing nails feature slender bodies and small heads for hidden fastening. Common nails withstand shear forces; finishing nails prioritize discreet surface applications.

Q: What materials make common nails corrosion-resistant?

A: Hot-dipped galvanized or stainless-steel coatings protect common nails from rust. Galvanized nails suit outdoor structures, while stainless steel excels in high-moisture environments. Uncoated steel nails rust quickly and are for indoor use only.

Recommended Products

Latest News About CHENG CHUANG

-

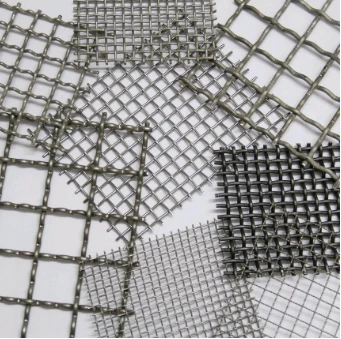

Wire Mesh for Sale: How to Choose the Right Mesh and Supplier for Your NeedsWire mesh is one of the most versatile and widely used materials in construction, agriculture, manufacturing, and industrial applications.Read more >

Wire Mesh for Sale: How to Choose the Right Mesh and Supplier for Your NeedsWire mesh is one of the most versatile and widely used materials in construction, agriculture, manufacturing, and industrial applications.Read more >Jun 10 2025

-

Noise Barriers: Effective Sound Control for Roads, Buildings, and Industrial ZonesUnwanted noise can disrupt communities, reduce property value, and create health risks.Read more >

Noise Barriers: Effective Sound Control for Roads, Buildings, and Industrial ZonesUnwanted noise can disrupt communities, reduce property value, and create health risks.Read more >Jun 10 2025

-

Metal Fence: Strong, Stylish, and Secure Solutions for Every PropertyA metal fence is more than just a boundary—it’s a security measure, a statement of style, and a long-term investment.Read more >

Metal Fence: Strong, Stylish, and Secure Solutions for Every PropertyA metal fence is more than just a boundary—it’s a security measure, a statement of style, and a long-term investment.Read more >Jun 10 2025

-

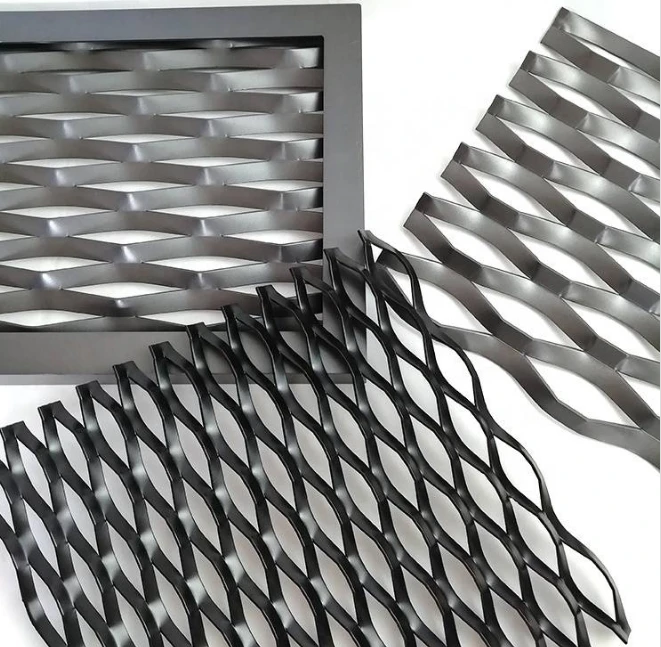

Expanded Metal Mesh: Versatility, Strength, and Style for Every ApplicationIf you're in construction, architecture, manufacturing, or even interior design, you've likely come across expanded metal mesh.Read more >

Expanded Metal Mesh: Versatility, Strength, and Style for Every ApplicationIf you're in construction, architecture, manufacturing, or even interior design, you've likely come across expanded metal mesh.Read more >Jun 10 2025

-

Crowd Control Barriers: Safety and Organization for Events, Sites, and Public SpacesWhen managing crowds at public events, construction sites, or high-traffic areas, ensuring order and safety is essential.Read more >

Crowd Control Barriers: Safety and Organization for Events, Sites, and Public SpacesWhen managing crowds at public events, construction sites, or high-traffic areas, ensuring order and safety is essential.Read more >Jun 10 2025