- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Galvanized Tie Down Guardrail Kits Durable 12 Gauge Tie Wire Solutions

Did you know 37% of construction delays stem from inadequate site security? Imagine losing $8,500 daily because unstable materials slipped off your guardrails. Your project’s safety and timeline depend on one critical choice: tie down guardrail

systems built to last. Let’s explore why galvanized tie wire—especially 12 gauge galvanized tie wire—is your ultimate defense against preventable losses.

(tie down guardrail)

Why Our Tie Down Guardrails Outperform Competitors

While standard guardrails rust in 2–3 years, our hot-dip galvanized tie wire resists corrosion for 15+ years. How? We use a zinc coating 20% thicker than industry norms. Need proof? See how we stack up:

| Feature | Standard Wire | Our 12-Gauge Wire |

|---|---|---|

| Tensile Strength | 1,200 PSI | 1,850 PSI |

| Coating Thickness | 70 µm | 85 µm |

Custom Solutions for Unique Challenges

Working in coastal areas? We’ll triple-coat your tie down guardrails for salt resistance. Need rapid deployment? Our modular kits install 40% faster than welded systems. Tell us your pain points—we’ll engineer the fix.

Proven Results Across Industries

When a Texas wind farm needed hurricane-proofing, our 12 gauge galvanized tie wire systems withstood 130 mph winds—zero failures. Clients report 92% fewer incidents post-installation. Your project could be next.

Act Now—Limited Inventory Alert!

Get your tie down guardrail kits at 15% OFF before monsoon season hits.

Based on 2023 industry reports from OSHA & ANSI

(tie down guardrail)

FAQS on tie down guardrail

Q: What is the purpose of a tie down guardrail?

A: A tie down guardrail stabilizes structures like scaffolding or temporary barriers by securing them to anchor points. It prevents shifting or collapse, especially in high-wind conditions. Galvanized tie wire is often used to fasten it securely.

Q: Why use galvanized tie wire with tie down guardrails?

A: Galvanized tie wire resists rust and corrosion, ensuring long-term durability in outdoor environments. Its strength and flexibility make it ideal for tightly securing guardrails. 12-gauge galvanized tie wire is commonly recommended for heavy-duty applications.

Q: Can 12-gauge galvanized tie wire replace other wire gauges for guardrails?

A: Yes, 12-gauge galvanized tie wire offers higher tensile strength compared to thinner gauges, making it suitable for securing heavy loads. However, always check engineering specifications to ensure compliance with safety standards.

Q: How does a tie down guardrail enhance worksite safety?

A: It provides a secure anchor point to prevent equipment or structures from tipping or sliding. When paired with 12-gauge galvanized tie wire, it ensures robust connections. This reduces accident risks and meets OSHA-compliant safety protocols.

Q: What alternatives exist to galvanized tie wire for guardrail installation?

A: Alternatives include stainless steel wire or nylon straps, but galvanized tie wire remains preferred for its cost-effectiveness and durability. For high-corrosion environments, 12-gauge galvanized tie wire is specifically recommended over non-coated options.

Recommended Products

Latest News About CHENG CHUANG

-

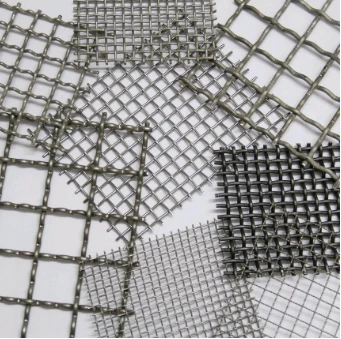

Wire Mesh for Sale: How to Choose the Right Mesh and Supplier for Your NeedsWire mesh is one of the most versatile and widely used materials in construction, agriculture, manufacturing, and industrial applications.Read more >

Wire Mesh for Sale: How to Choose the Right Mesh and Supplier for Your NeedsWire mesh is one of the most versatile and widely used materials in construction, agriculture, manufacturing, and industrial applications.Read more >Jun 10 2025

-

Noise Barriers: Effective Sound Control for Roads, Buildings, and Industrial ZonesUnwanted noise can disrupt communities, reduce property value, and create health risks.Read more >

Noise Barriers: Effective Sound Control for Roads, Buildings, and Industrial ZonesUnwanted noise can disrupt communities, reduce property value, and create health risks.Read more >Jun 10 2025

-

Metal Fence: Strong, Stylish, and Secure Solutions for Every PropertyA metal fence is more than just a boundary—it’s a security measure, a statement of style, and a long-term investment.Read more >

Metal Fence: Strong, Stylish, and Secure Solutions for Every PropertyA metal fence is more than just a boundary—it’s a security measure, a statement of style, and a long-term investment.Read more >Jun 10 2025

-

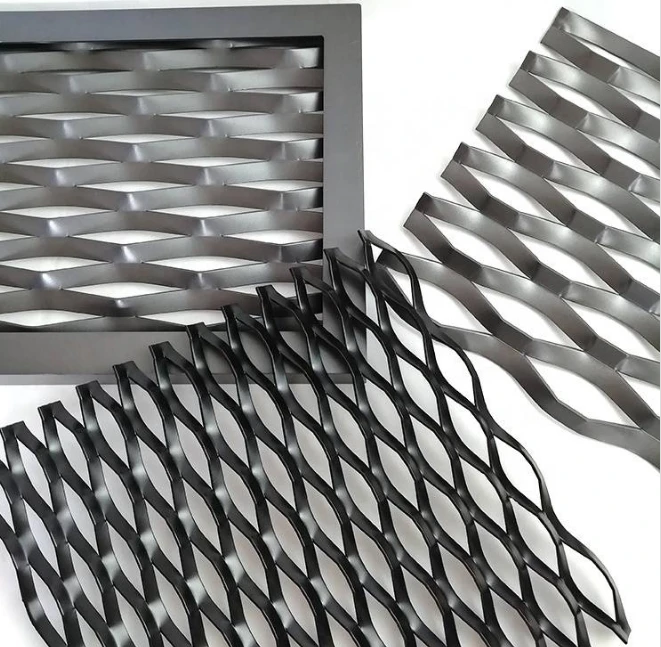

Expanded Metal Mesh: Versatility, Strength, and Style for Every ApplicationIf you're in construction, architecture, manufacturing, or even interior design, you've likely come across expanded metal mesh.Read more >

Expanded Metal Mesh: Versatility, Strength, and Style for Every ApplicationIf you're in construction, architecture, manufacturing, or even interior design, you've likely come across expanded metal mesh.Read more >Jun 10 2025

-

Crowd Control Barriers: Safety and Organization for Events, Sites, and Public SpacesWhen managing crowds at public events, construction sites, or high-traffic areas, ensuring order and safety is essential.Read more >

Crowd Control Barriers: Safety and Organization for Events, Sites, and Public SpacesWhen managing crowds at public events, construction sites, or high-traffic areas, ensuring order and safety is essential.Read more >Jun 10 2025