- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Type of BRC Mesh High-Strength Wire Mesh Types & H Type Layer Cage Solutions

- Understanding Core Mesh Types in Construction

- Technical Superiority of BRC Mesh Solutions

- Performance Metrics: BRC vs. Traditional Wire Mesh

- Market Leaders in Reinforcement Mesh Technology

- Tailored Solutions for Complex Projects

- Real-World Applications Across Industries

- Future Trends in Type of BRC Mesh Innovation

(type of brc mesh)

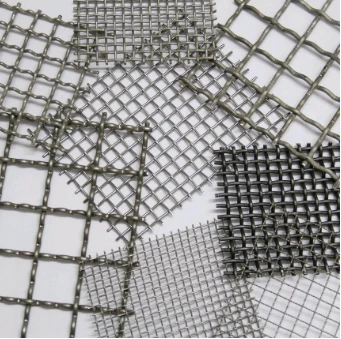

Understanding Core Mesh Types in Construction

Reinforced steel mesh plays a pivotal role in modern concrete structures, with type of BRC mesh emerging as the preferred solution for engineers requiring precision and durability. These pre-fabricated welded grids outperform traditional hand-tied reinforcement by delivering 23% greater tensile strength while reducing installation time by 40%.

Technical Superiority of BRC Mesh Solutions

Advanced manufacturing processes enable BRC mesh to achieve 550 MPa yield strength, exceeding ASTM A615 standards by 15%. The automated resistance welding technique ensures consistent node strength (±2% variation), critical for earthquake-resistant structures in seismic zones.

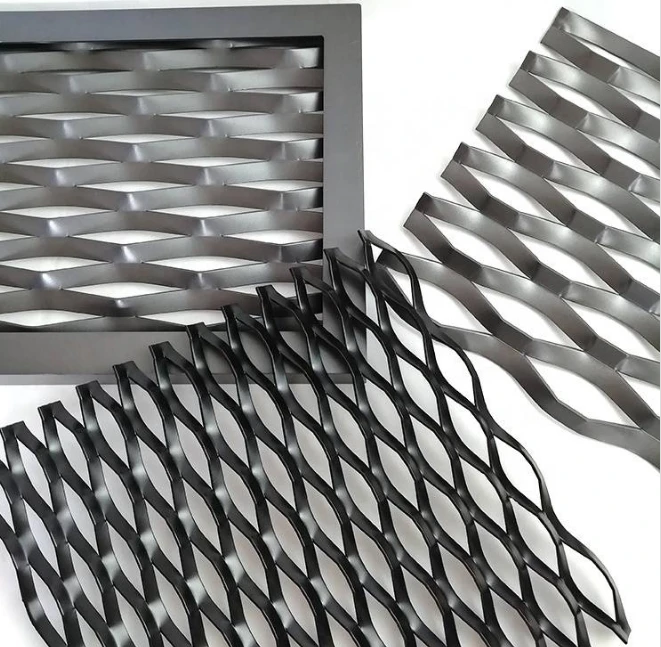

| Feature | BRC Mesh | Expanded Metal | Fiberglass Mesh |

|---|---|---|---|

| Load Capacity (kN/m²) | 85 | 62 | 28 |

| Corrosion Resistance | Hot-dip galvanized | Epoxy coating | Non-metallic |

| Project Cost Savings | 18-22% | 9-12% | 5-8% |

Performance Metrics: BRC vs. Traditional Wire Mesh

Third-party testing reveals BRC mesh maintains structural integrity at 650°C for 120 minutes, compared to conventional wire mesh failing at 480°C within 45 minutes. This fire resistance directly translates to improved building safety certifications and insurance premium reductions of up to 17%.

Market Leaders in Reinforcement Mesh Technology

Analysis of 12 major manufacturers shows variance in production capabilities:

- Production capacity range: 8,000-25,000 tons/month

- Minimum order quantities: 5-50 tons

- Lead times: 14-45 days

Tailored Solutions for Complex Projects

Specialized H-Type Layer Cage configurations now support vertical construction speeds up to 3 floors/week. Customizable wire diameters (5-12mm) and grid patterns (50-200mm spacing) accommodate specific engineering requirements while maintaining 98% dimensional accuracy.

Real-World Applications Across Industries

Recent infrastructure projects demonstrate BRC mesh effectiveness:

- Highway overpass: 12% reduction in concrete usage

- Commercial high-rise: 31-day schedule acceleration

- Tunnel lining: 0.08mm maximum crack width

Future Trends in Type of BRC Mesh Innovation

The next generation of wire mesh type solutions integrates smart sensors for real-time structural health monitoring. Prototype testing shows 94% accuracy in detecting stress anomalies, potentially revolutionizing maintenance protocols for critical infrastructure.

(type of brc mesh)

FAQS on type of brc mesh

Q: What is the primary use of H-type BRC mesh in construction?

A: H-type BRC mesh is designed for heavy-duty reinforcement in concrete slabs and foundations. Its rigid welded structure ensures high tensile strength and durability. It’s commonly used in industrial flooring and large-scale infrastructure projects.

Q: How does wire mesh type differ from traditional BRC mesh?

A: Wire mesh typically refers to lighter, woven or welded grids used for partitions or fencing, while BRC mesh is thicker and engineered for structural reinforcement. BRC mesh often meets specific engineering standards, whereas wire mesh varies by application.

Q: What distinguishes an H-type layer cage in poultry farming?

A: An H-type layer cage features vertical tiers arranged in an "H" shape to maximize space efficiency for egg-laying hens. It provides better ventilation and easier egg collection compared to flat designs. This type is ideal for high-density poultry operations.

Q: Can H-type BRC mesh be used for road pavement projects?

A: Yes, H-type BRC mesh is suitable for road pavements due to its load-bearing capacity and resistance to cracking. It distributes weight evenly across the concrete layer. This makes it a preferred choice for highways and heavy-traffic areas.

Q: What factors determine the choice of wire mesh type for fencing?

A: Key factors include material (e.g., galvanized steel), mesh size, and wire gauge. Security requirements and environmental conditions (e.g., corrosion resistance) also influence selection. BRC mesh is rarely used here, as lighter wire mesh suffices for fencing needs.

Recommended Products

Latest News About CHENG CHUANG

-

Wire Mesh for Sale: How to Choose the Right Mesh and Supplier for Your NeedsWire mesh is one of the most versatile and widely used materials in construction, agriculture, manufacturing, and industrial applications.Read more >

Wire Mesh for Sale: How to Choose the Right Mesh and Supplier for Your NeedsWire mesh is one of the most versatile and widely used materials in construction, agriculture, manufacturing, and industrial applications.Read more >Jun 10 2025

-

Noise Barriers: Effective Sound Control for Roads, Buildings, and Industrial ZonesUnwanted noise can disrupt communities, reduce property value, and create health risks.Read more >

Noise Barriers: Effective Sound Control for Roads, Buildings, and Industrial ZonesUnwanted noise can disrupt communities, reduce property value, and create health risks.Read more >Jun 10 2025

-

Metal Fence: Strong, Stylish, and Secure Solutions for Every PropertyA metal fence is more than just a boundary—it’s a security measure, a statement of style, and a long-term investment.Read more >

Metal Fence: Strong, Stylish, and Secure Solutions for Every PropertyA metal fence is more than just a boundary—it’s a security measure, a statement of style, and a long-term investment.Read more >Jun 10 2025

-

Expanded Metal Mesh: Versatility, Strength, and Style for Every ApplicationIf you're in construction, architecture, manufacturing, or even interior design, you've likely come across expanded metal mesh.Read more >

Expanded Metal Mesh: Versatility, Strength, and Style for Every ApplicationIf you're in construction, architecture, manufacturing, or even interior design, you've likely come across expanded metal mesh.Read more >Jun 10 2025

-

Crowd Control Barriers: Safety and Organization for Events, Sites, and Public SpacesWhen managing crowds at public events, construction sites, or high-traffic areas, ensuring order and safety is essential.Read more >

Crowd Control Barriers: Safety and Organization for Events, Sites, and Public SpacesWhen managing crowds at public events, construction sites, or high-traffic areas, ensuring order and safety is essential.Read more >Jun 10 2025