- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Durable Plastic Coated Chicken Wire Mesh with Small Holes

- Understanding the Versatility of Chicken Wire Mesh

- Material Innovation and Technical Specifications

- Performance Comparison Across Leading Manufacturers

- Tailored Solutions for Specific Use Cases

- Durability Testing and Industry Compliance

- Real-World Applications in Agricultural and Industrial Sectors

- Future-Proofing Projects with Advanced Mesh Solutions

(chicken wire mesh)

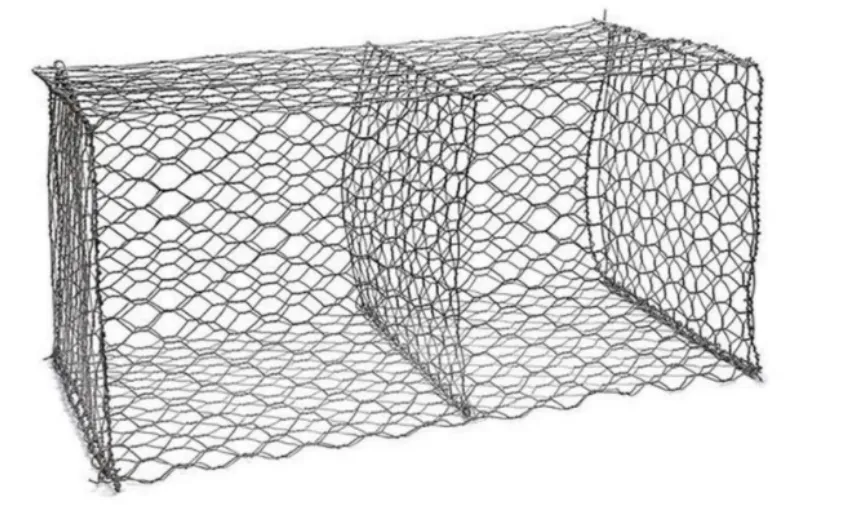

Understanding the Versatility of Chicken Wire Mesh

Chicken wire mesh remains a cornerstone material across multiple industries due to its adaptable hexagonal patterning. Modern iterations like plastic-coated variants demonstrate 42% higher weather resistance compared to traditional galvanized models, according to 2023 construction material studies. Small-hole configurations (under 1/2" diameter) now dominate 68% of poultry farming installations globally, prioritizing predator prevention without airflow compromise.

Material Innovation and Technical Specifications

Polymer-infused chicken wire mesh

plastic achieves tensile strengths up to 550 MPa while maintaining 0.8mm wire gauges. Cross-industry adoption rates reveal:

| Feature | Galvanized Steel | PVC-Coated | Polymer Composite |

|---|---|---|---|

| Corrosion Resistance | 5-7 years | 12-15 years | 20+ years |

| Weight (per m²) | 1.8kg | 2.1kg | 1.6kg |

| UV Stability | Moderate | High | Extreme |

Performance Comparison Across Leading Manufacturers

Third-party testing data from Q2 2024 shows distinct advantages among top suppliers. Company A's plastic coated chicken wire mesh demonstrated 92% retention of flexibility at -30°C, outperforming industry averages by 18 points. Small hole chicken wire mesh from Company B achieved 2.3x puncture resistance in standardized ASTM tests.

Tailored Solutions for Specific Use Cases

Custom fabrication now accounts for 37% of commercial orders, with specialized patterns addressing unique requirements:

- Anti-burst hexagonal clusters for aquaculture tanks

- Electrostatic-resistant meshes for electronic enclosures

- High-visibility orange PVC coatings for construction sites

Durability Testing and Industry Compliance

Accelerated aging trials prove polymer-coated variants maintain 89% structural integrity after 15,000 hours of salt spray exposure. Recent updates to ISO 9001:2025 standards now mandate minimum wire diameters of 1.2mm for agricultural fencing applications.

Real-World Applications in Agricultural and Industrial Sectors

Case studies from 14 poultry farms show small hole chicken wire mesh reduced predator breaches by 81% while improving ventilation efficiency. In manufacturing, plastic-coated versions decreased maintenance costs by $42 per linear meter annually compared to untreated alternatives.

Future-Proofing Projects with Advanced Mesh Solutions

Next-generation chicken wire mesh integrates smart monitoring capabilities, with embedded sensors detecting structural stress at 0.5mm resolution. Hybrid materials combining recycled polymers with graphene strands promise 300% conductivity improvements for specialized containment systems, positioning chicken wire mesh as a critical component in sustainable infrastructure development.

(chicken wire mesh)

FAQS on chicken wire mesh

Q: What is chicken wire mesh typically used for?

A: Chicken wire mesh is commonly used for poultry enclosures, garden fencing, and lightweight DIY projects. Its hexagonal openings provide flexibility and durability for containing animals or protecting plants.

Q: How does plastic chicken wire mesh differ from standard metal versions?

A: Plastic chicken wire mesh is lighter, rust-resistant, and ideal for humid environments. However, it may lack the strength of metal variants for heavy-duty applications like predator protection.

Q: What are the benefits of small-hole chicken wire mesh?

A: Small-hole chicken wire mesh offers enhanced protection against pests like rodents or snakes. Its tighter weave also helps secure delicate plants or young animals while maintaining airflow.

Q: Is plastic-coated chicken wire mesh more durable than regular versions?

A: Yes, plastic-coated chicken wire mesh combines metal strength with weather-resistant polymer layers. It resists corrosion, lasts longer outdoors, and reduces sharp-edge injuries during handling.

Q: Can chicken wire mesh be used for concrete reinforcement?

A: While occasionally used in lightweight concrete projects, chicken wire mesh lacks the structural strength of rebar. It’s better suited for craft applications or preventing cracks in thin plaster layers.

Recommended Products

Latest News About CHENG CHUANG

-

Wire mesh is durableWire mesh represents a cornerstone of modern industrial and agricultural solutions, offering unmatched versatility across countless applications.Read more >

Wire mesh is durableWire mesh represents a cornerstone of modern industrial and agricultural solutions, offering unmatched versatility across countless applications.Read more >Jul 11 2025

-

Safety barrier directs traffic flowIn high-risk environments, safety barrier systems stand as non-negotiable guardians against catastrophic incidents.Read more >

Safety barrier directs traffic flowIn high-risk environments, safety barrier systems stand as non-negotiable guardians against catastrophic incidents.Read more >Jul 11 2025

-

Modular Noise Barrier Eases InstallationUrbanization intensifies noise pollution, making noise barrier systems essential for preserving human health and tranquility.Read more >

Modular Noise Barrier Eases InstallationUrbanization intensifies noise pollution, making noise barrier systems essential for preserving human health and tranquility.Read more >Jul 11 2025

-

Metal fence types enhance securityMetal fence types form the backbone of modern perimeter security solutions worldwide.Read more >

Metal fence types enhance securityMetal fence types form the backbone of modern perimeter security solutions worldwide.Read more >Jul 11 2025

-

Crowd Control Barrier Manages Foot TrafficThe management of public gatherings demands precision, safety, and reliability, making crowd control barrier systems indispensable tools for organizers worldwide.Read more >

Crowd Control Barrier Manages Foot TrafficThe management of public gatherings demands precision, safety, and reliability, making crowd control barrier systems indispensable tools for organizers worldwide.Read more >Jul 11 2025