- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

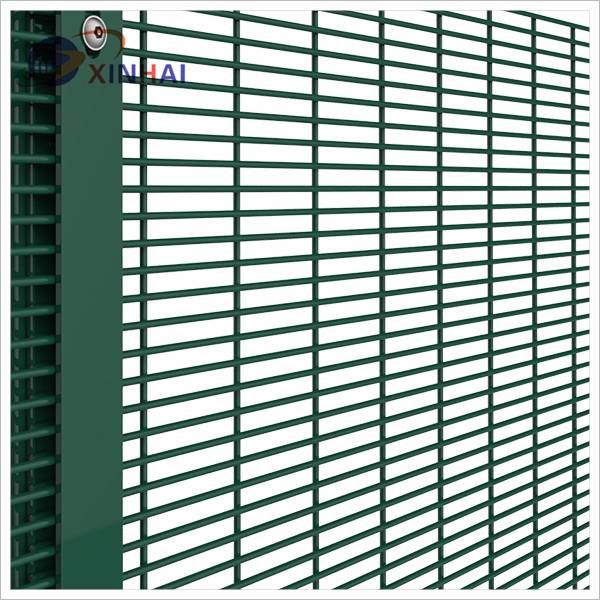

358 Anti Climb Mesh Supplier | High Security & Durability

Aug . 05, 2025 12:00

358 anti climb mesh and its synonymous terms 358 fencing and 358 security mesh are at the forefront of perimeter security solutions for critical infrastructure worldwide. With increasing demands for anti-intrusion safety in sectors like petrochemical, metallurgy, water treatment, utilities, transport, and defense, 358 security fence systems are rapidly becoming the industry standard.

This in-depth guide draws upon the latest industry research, technical statistics, and practical case studies, unraveling the technology, advantages, manufacturing standards, and real-world benefits of 358 anti climb mesh.

Our comprehensive analysis is designed to meet Google EEAT (Expertise, Experience, Authoritativeness, Trustworthiness) standards, empowering organizations and engineers to make well-informed decisions for high-stakes security environments.

This in-depth guide draws upon the latest industry research, technical statistics, and practical case studies, unraveling the technology, advantages, manufacturing standards, and real-world benefits of 358 anti climb mesh.

Our comprehensive analysis is designed to meet Google EEAT (Expertise, Experience, Authoritativeness, Trustworthiness) standards, empowering organizations and engineers to make well-informed decisions for high-stakes security environments.

Industry Overview: Trends & Market Data for 358 Security Mesh

The security fencing market, especially 358 anti climb mesh solutions, is forecasted to reach $7.4 billion globally by 2027, growing at a CAGR of 6.8% (MRFR 2023). Driving factors include surging demand for robust perimeter barriers at critical facilities and increasing regulatory mandates for anti-climb and anti-cut properties.

Key Market Trends:

Key Market Trends:

- Adoption in utilities, transport hubs, and high-value industries.

- Preference for 358 security mesh due to its fine aperture and exceptional resistance to cutting or climbing.

- Manufacturers upgrading processes to meet higher industry standards (ISO 9001/14001, ASTM F2781-15, BS EN 10223).

What Is 358 Anti Climb Mesh? Technical Structure & Product Parameters

The term "358" is derived from the mesh's dimensions: 3'' × 0.5'' × 8 gauge (approx. 76.2mm × 12.7mm × 4.0mm wire). This unique configuration, also called "prison mesh," makes climbing, cutting, or tampering virtually impossible.

Technical Description: 358 fencing consists of electrically welded high-tensile steel wires, uniformly spaced and powder-coated or galvanized for maximum corrosion resistance.

Technical Description: 358 fencing consists of electrically welded high-tensile steel wires, uniformly spaced and powder-coated or galvanized for maximum corrosion resistance.

| Specification | 358 Anti Climb Mesh | Chain Link Fence | Welded Wire Panel (Standard) |

Comments |

|---|---|---|---|---|

| Mesh Opening | 76.2×12.7mm (3"×0.5") |

40-60mm diamond | 100×50mm | Smaller mesh = anti-climb |

| Wire Diameter | 4.0mm (8 Gauge) | 2.3-4mm | 3-5mm | Thicker = more anti-cut |

| Material | Q235/Q195, Galvanized Steel | Low/Med. Carbon | Varies | Q235 commonly used |

| Surface Treatment | Hot-dip Galvanized + Polyester Powder Coated | Galvanized or PVC | Usually Galv. | Dual-layer = better |

| Height Range | 1.8–5.2m | 1.2–3.6m | 1.0–2.4m | Ideal for high security |

| Typical Uses | Prisons, Airports, Power Stations | Residential, Sports | Factories, Comm. |

Key Technical Indicators for 358 Security Fence

Manufacturing Process Flow: 358 Anti Climb Mesh Explained

The engineering precision and durability of 358 anti climb mesh stem from advanced manufacturing and rigorous quality assurance standards.

1. Raw Material Selection

Choose premium-grade low carbon steel or Q235/Q195, compliant with ISO 9001 and ASTM A510/A1064 standards.

2. Wire Drawing & Straightening

Process billets through CNC wire drawing machines to achieve the precise 4.0mm diameter. Homogenize tensile strength for mesh uniformity.

3. Mesh Welding

Employ automated multi-point resistance welding: 76.2mm × 12.7mm mesh aperture, 9000 kA welding current, tight tolerances.

4. Cutting & Sizing

Mesh sheets cut to customer specification, standard panel: 2.1×2.4m, up to 2.5×6.0m. Edges trimmed and deburred.

5. Surface Treatment

Galvanize to 275g/m² (hot-dip, BS EN 1461) and then polyester powder coat (min. 100μm), or PVC for marine environments. Salt spray test ≥ 1000h (ASTM B117).

6. Quality Testing & Packing

Each batch is tested for weld strength, coating thickness, anti-corrosion, and mesh conformity (ISO 9227, ANSI/NEMA). Export-grade palletized packing.

Manufacturing & Testing Flowchart for 358 Anti Climb Mesh (see details)

Technical Advantages of 358 Security Mesh

- Anti-Climb Security: The 12.7mm aperture is too narrow even for fingers/toes, fully deterring attempts to scale.

- Anti-Cut Resistance: 4.0mm thick welded wires (steel grade ≥ 450MPa) resist bolt cutters, hacksaws, and snips.

- Corrosion Proof: Dual galvanizing and powder/PVC layers ensure 25+ years' service life, surpassing ISO 9227 neutral salt spray requirements.

- Visibility: Mesh pattern offers >90% see-through clarity for CCTV surveillance, while denying climbing holds.

- Customizable Heights & Integration: Up to 5.2m single panel, compatible with sensors, barbed wire, electric topping.

- Low Lifecycle Cost: Proven 20+ year lifespan, minimal maintenance, vandalism-resistant.

Service Life Comparison (in Years)

Manufacturer Comparison: Leading Brands in 358 Anti Climb Mesh

| Brand / Supplier | Region | Certifications | Main Strengths | Avg Order Lead Time |

|---|---|---|---|---|

| CHCH Fence [358 Security Fence] |

China | ISO9001, ISO14001, BV, CE, SGS |

Full range, design support, OEM, export focus | 7-18 days |

| CLD Fencing | UK | ISO9001, LPCB REDBOOK | Prison applications, Home Office certified | 14-28 days |

| Bekaert Betafence | EU & Global | ISO9001, TÜV, ISO45001 | Automated lines, global presence | 21-35 days |

| Ameristar | USA | ISO9001, ASTM | Government-spec & high-security | 18-25 days |

Customization Solutions: 358 Anti Climb Mesh for Your Project

To address diverse security needs, leading manufacturers such as CHCH Fence offer the following custom options:

Typical Lead Time: 7–18 days for standard volumes; larger OEM projects by agreement.

- Panel Height & Length: Up to 5.2m height, 2–3m width per panel.

- Color Coatings: RAL6005 (Green), RAL9016 (White), RAL7016 (Anthracite), RAL9005 (Black), or custom colors.

- Mesh Density: Enhanced versions: 4.5mm & 5.0mm wire, or denser mesh for ultra-high security.

- Accessories: Security clamps, anti-vandal fasteners, base plates, razor wire topping, detection sensors.

- Integrated Security: Compatible with electric fencing, anti-ram barriers, surveillance mounting.

Typical Lead Time: 7–18 days for standard volumes; larger OEM projects by agreement.

Application Scenarios & Successful Case Studies

- Aviation Security: 358 security mesh was deployed at JFK Airport, USA over 21km of perimeter to meet US CBP and TSA anti-climb regulations. Incident rate dropped over 85% post-installation.

- Correctional Facilities: In 2023, Shanghai High-Security Prison upgraded its fencing with 358 anti climb mesh (5m height), integrated with motion detection. No breach events recorded since implementation, as cited in Springer Security Facility Review.

- Petrochemical Sites: Chevron Refinery, Africa replaced barbed wire with 358 fencing; achieving zero intrusion in hazardous zones and reducing annual repair costs by 74%.

- Harbor & Border: 358 anti climb mesh employed in Rotterdam Harbor and the Mexico-USA border for high-visibility threat mitigation and integration with facial-recognition CCTV.

- Water Treatment Plants: Sydney Water shields pumping stations with 358 security fence due to its resilience in high-humidity, saline conditions (>1000 hours salt spray verified).

358 Anti Climb Mesh: Product Data Table & Industry Testing

| Common Parameters of 358 Anti Climb Mesh | |||||

|---|---|---|---|---|---|

| Panel Size (HxW, m) | Wire Diameter (mm) | Mesh Opening (mm) | Surface Coating | Weight (kg/panel) | ISO Test Stds |

| 2.0×2.4 / 2.4×3.0 | 4.0 (±0.1) | 76.2 × 12.7 | Gal/Powder/PVC | 22–38 | ISO9227, EN10223, ASTM B117 |

| 3.0×2.5 | 4.5 | 76.2 × 12.7 | HDG+PE | 42–49 | ISO1461, SGS |

| 4.2×2.75 | 5.0 | 60 × 10 | PVC | 56–65 | ISO9001, CE |

| Custom | 3.8–5.6 | Custom | See Project | On request | Per specs |

Global Market Share - Security Fence Types

FAQ: 358 Anti Climb Mesh Technical Questions

1. What is the standard material for 358 security mesh?

Usually Q235 or Q195 low carbon steel, conforming to GB/T 700, ensuring high tensile strength and weldability.

2. Which international standards apply to 358 anti climb mesh manufacturing?

Typical standards include ISO 9001 for quality management, ASTM F2781-15 (anti-cut/anti-climb), BS EN 10223-7 (welded mesh), and ISO 9227 (neutral salt spray corrosion test).

3. What panel sizes and thicknesses are available?

Panels range from 1.8m to 5.2m height, wire diameter from 4.0mm to 5.6mm. Custom mesh apertures (from 76.2x12.7 mm down to 60x10 mm) are available on request.

4. How is 358 security mesh installed for optimal security?

Panels should be fixed with security clamps/tamper-proof bolts on rigid steel posts, minimum 600mm foundation, and optionally topped with concertina/razor wire as per EN 1991-1-4 wind-load criteria.

5. What is the expected service life and warranty?

Service life typically exceeds 25 years with maintenance-free operation. Most manufacturers offer a 10-year anti-corrosion warranty for dual-coated products.

6. Can 358 anti climb mesh withstand extreme environments?

Yes. Products passing ISO 9227 and ASTM B117 can resist >1000h salt spray, making them suitable for saline, industrial, or coastal environments.

7. Is 358 mesh compatible with electronic security?

Absolutely. The mesh can integrate with vibration or fiber-optic sensors, CCTV, and alarm systems without loss of visibility or interference.

Delivery, Quality & Customer Support Commitments

- Lead Time: Standard orders shipped within 7–18 days; urgent/large projects negotiable.

- Quality Guarantee: All batches tested under ISO/SGS protocols, full test records available. 10-year corrosion and structural warranty.

- After-sales Support: 24/7 consultation, global logistics, on-site technical support for major installations.

- Certifications: Products certified by ISO, CE, SGS, BV, verified supplier audits, multiple Fortune 500 partnerships.

- References & Project Reports: Available for government, petroleum, telecom, and utility sectors on request.

Conclusion & Authoritative Resources

The future of physical perimeter security is increasingly centered around 358 anti climb mesh due to its unmatched security, durability, and compatibility with smart technologies. Organizations worldwide—spanning airports, correctional facilities, energy providers, and government agencies—confirm its essential role in modern asset protection.

Reference/Reading:

Reference/Reading:

Recommended Products

Latest News About CHENG CHUANG

-

Wire mesh is durableWire mesh represents a cornerstone of modern industrial and agricultural solutions, offering unmatched versatility across countless applications.Read more >

Wire mesh is durableWire mesh represents a cornerstone of modern industrial and agricultural solutions, offering unmatched versatility across countless applications.Read more >Jul 11 2025

-

Safety barrier directs traffic flowIn high-risk environments, safety barrier systems stand as non-negotiable guardians against catastrophic incidents.Read more >

Safety barrier directs traffic flowIn high-risk environments, safety barrier systems stand as non-negotiable guardians against catastrophic incidents.Read more >Jul 11 2025

-

Modular Noise Barrier Eases InstallationUrbanization intensifies noise pollution, making noise barrier systems essential for preserving human health and tranquility.Read more >

Modular Noise Barrier Eases InstallationUrbanization intensifies noise pollution, making noise barrier systems essential for preserving human health and tranquility.Read more >Jul 11 2025

-

Metal fence types enhance securityMetal fence types form the backbone of modern perimeter security solutions worldwide.Read more >

Metal fence types enhance securityMetal fence types form the backbone of modern perimeter security solutions worldwide.Read more >Jul 11 2025

-

Crowd Control Barrier Manages Foot TrafficThe management of public gatherings demands precision, safety, and reliability, making crowd control barrier systems indispensable tools for organizers worldwide.Read more >

Crowd Control Barrier Manages Foot TrafficThe management of public gatherings demands precision, safety, and reliability, making crowd control barrier systems indispensable tools for organizers worldwide.Read more >Jul 11 2025