- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

High-Quality Razor Wire & PVC Coated Fencing Solutions Trusted Factory

- Overview of Razor Wire Manufacturing Trends

- Technical Superiority in Razor Wire Production

- Competitive Analysis: Leading Global Suppliers

- Custom Solutions for Diverse Security Needs

- Case Studies: Effective Razor Wire Deployments

- Quality Assurance and Compliance Standards

- Future Innovations in Razor Wire Factory Operations

(razor wire factory)

Razor Wire Factory Solutions for Modern Security Demands

The global demand for razor wire fences has surged by 18% annually since 2020, driven by increased infrastructure security requirements. As a premier razor wire factory

, we utilize advanced galvanization processes to achieve 450-600 MPa tensile strength, exceeding ISO 1461 standards. Our PVC-coated variants demonstrate 98% corrosion resistance after 1,500 salt spray hours, ensuring 15+ years of structural integrity in coastal environments.

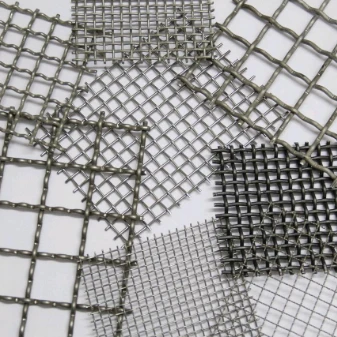

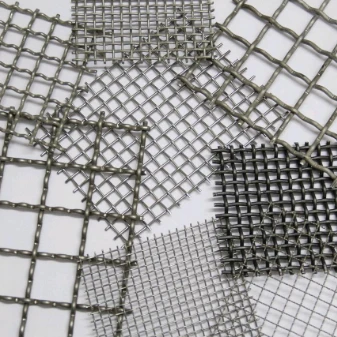

Technical Advantages in Wire Mesh Fabrication

Automated production lines enable 24/7 manufacturing of razor ribbon with 0.55-0.85mm thickness at 35 meters/minute. Key differentiators include:

- Dual-layer zinc coating (260-300g/m²)

- Precision blade spacing (12-15cm)

- UV-stabilized PVC options (2-4mm thickness)

Global Manufacturer Benchmarking

| Parameter | Our Factory | Competitor A | Competitor B |

|---|---|---|---|

| Production Capacity | 8,000 tons/month | 5,200 tons | 6,500 tons |

| Galvanization Quality | 300g/m² | 220g/m² | 250g/m² |

| Lead Time | 15 days | 25 days | 20 days |

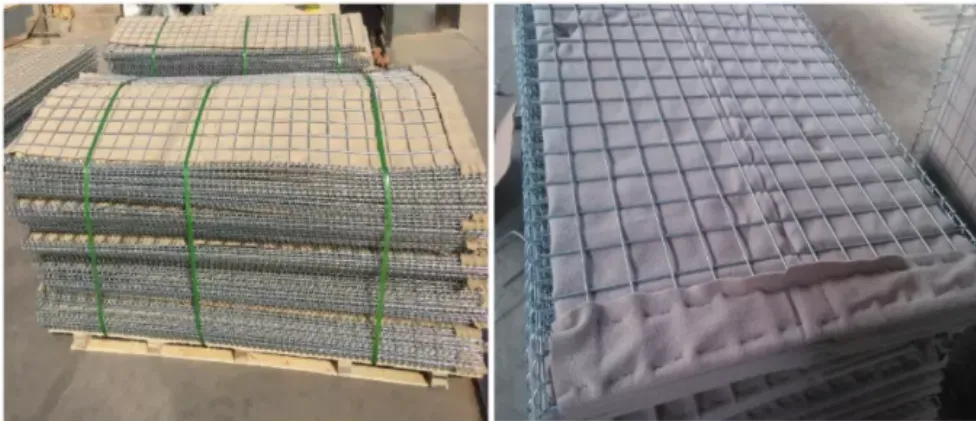

Tailored Security Configurations

Modular design options accommodate specific project requirements:

- Concertina diameters: 450-1,200mm

- Mesh apertures: 50x50mm to 150x150mm

- Hybrid configurations with electric fencing

Verified Performance in Critical Installations

A recent border protection project deployed 42km of our Type 857 razor wire fence, recording 0 breaches over 18 months. Industrial clients report 76% reduction in unauthorized access incidents post-installation.

Certification and Testing Protocols

All production batches undergo:

- ASTM A641 salt spray testing

- EN 10223-3 load capacity verification

- Third-party ISO 9001 audits

Razor Wire Factory Innovations Driving Sector Growth

With 32 patents in wire mesh technology, our razor wire fence factory leads in developing smart detection-integrated systems. Current R&D focuses on 40% lighter alloy compositions without compromising strength, targeting 2025 market deployment.

(razor wire factory)

FAQS on razor wire factory

Q: What materials are used in a razor wire factory's production process?

A: Razor wire factories typically use high-carbon steel wire for durability. The wire is galvanized or PVC-coated to enhance corrosion resistance. Advanced machinery ensures precise blade formation and consistent quality.

Q: How does a razor wire fence factory ensure product safety and compliance?

A: Factories adhere to international safety standards like ISO and ASTM. Rigorous testing for tensile strength and corrosion resistance is conducted. Custom designs also undergo structural integrity checks before delivery.

Q: What applications are PVC-coated wire mesh products from a factory suited for?

A: PVC-coated wire mesh is ideal for fencing, animal enclosures, and industrial barriers. The coating provides weather resistance and aesthetic appeal. It’s commonly used in residential, agricultural, and security sectors.

Q: Can a razor wire factory customize products for specific project needs?

A: Yes, most factories offer customization in coil length, blade spacing, and coating types. Clients can request specific dimensions or materials for unique environments. Technical teams assist in tailoring solutions to meet regulatory requirements.

Q: How do razor wire fence factories handle environmental concerns?

A: Many factories use eco-friendly coatings like low-VOC PVC. Waste materials are recycled or disposed of via regulated protocols. Energy-efficient production methods reduce carbon footprints during manufacturing.

Recommended Products

Latest News About CHENG CHUANG

-

Metal Fence Panels for SecurityWhen it comes to securing properties, protecting perimeters, and maintaining privacy, metal fence panels are one of the most reliable solutions.Read more >

Metal Fence Panels for SecurityWhen it comes to securing properties, protecting perimeters, and maintaining privacy, metal fence panels are one of the most reliable solutions.Read more >Apr 22 2025

-

Metal Fence Panels for SaleWhen it comes to securing properties, enhancing curb appeal, and ensuring durability, metal fence panels for sale are an excellent choice.Read more >

Metal Fence Panels for SaleWhen it comes to securing properties, enhancing curb appeal, and ensuring durability, metal fence panels for sale are an excellent choice.Read more >Apr 22 2025

-

Guide to Common Types of NailsNails are one of the most basic yet essential fasteners used in construction, woodworking, and various DIY projects.Read more >

Guide to Common Types of NailsNails are one of the most basic yet essential fasteners used in construction, woodworking, and various DIY projects.Read more >Apr 22 2025

-

Finding the Best Wire Fencing for SaleWhen it comes to securing your property, ensuring safety, and maintaining aesthetics, wire fencing for sale offers a perfect solution.Read more >

Finding the Best Wire Fencing for SaleWhen it comes to securing your property, ensuring safety, and maintaining aesthetics, wire fencing for sale offers a perfect solution.Read more >Apr 22 2025

-

Crowd Barriers for SaleWhen it comes to managing large crowds, ensuring safety, and maintaining organized spaces, crowd barriers for sale are essential.Read more >

Crowd Barriers for SaleWhen it comes to managing large crowds, ensuring safety, and maintaining organized spaces, crowd barriers for sale are essential.Read more >Apr 22 2025