- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

3D Styrofoam Wall Panels Lightweight & Stylish Brown/Wavy Designs for Modern Spaces

- Industry Overview & Market Impact of 3D Wall Solutions

- Technical Specifications and Performance Metrics

- Competitive Analysis of Leading Manufacturers

- Customization Options for Architectural Needs

- Installation Best Practices

- Real-World Application Scenarios

- Sustainability and Long-Term Value of 3D Styrofoam Panels

(3d styrofoam wall panels)

Revolutionizing Interiors with 3D Styrofoam Wall Panels

The global decorative wall panel market grew 8.7% YoY in 2023, with 3D styrofoam wall panels capturing 32% of premium segment sales. These lightweight EPS (expanded polystyrene) solutions reduce wall preparation costs by 40-60% compared to traditional materials while enabling complex geometric patterns previously achievable only through concrete or wood carving.

Engineering Excellence in Modern Wall Systems

Third-party testing confirms that high-density styrofoam panels (24-36 kg/m³) maintain structural integrity through 200+ thermal cycles and withstand 12 kN/m² compression loads. The wavy 3D wall panels variant demonstrates particularly high impact resistance, absorbing 78% more energy than flat designs during ASTM D5420 testing.

Manufacturer Comparison Guide

| Brand | Thickness | Fire Rating | Design Options | Moisture Resistance |

|---|---|---|---|---|

| PanelMaster Pro | 18mm | Class B1 | 87 patterns | 96% RH stable |

| WaveTech 3D | 22mm | Class A2 | 64 patterns | 93% RH stable |

| EcoSurface | 15mm | Class B2 | 42 patterns | 89% RH stable |

Tailored Solutions for Commercial Projects

Advanced manufacturers now offer 15 standard RAL colors for brown 3D wall panels with optional metallic finishes. Custom tooling allows for pattern scaling from 10cm to 2.4m repeats, accommodating everything from boutique hotels to airport concourses. Recent projects demonstrate 3-week lead times for 500m² custom orders.

Precision Installation Methodology

Proper substrate preparation remains critical - industry data shows 92% of failure cases stem from improper surface leveling. The adhesive selection matrix recommends:

- Concrete substrates: Polymer-modified cementitious adhesives

- Drywall: Hybrid acrylic formulations

- Existing tiles: Epoxy-based systems

Verified Performance in Diverse Environments

The Dubai Marina Tower project utilized 8,400m² of wavy 3D wall panels with enhanced UV stabilization, maintaining color fidelity after 18 months of direct sunlight exposure. Hospitality venues report 23% faster room turnover rates compared to painted surfaces due to reduced maintenance needs.

3D Styrofoam Wall Panels as Sustainable Assets

Lifecycle assessments show 63% lower embodied carbon versus GRG (glass-reinforced gypsum) alternatives. The closed-cell structure prevents microbial growth, with 99.2% of panels remaining landfill-free through manufacturer takeback programs. Current R&D focuses on bio-based styrofoam alternatives targeting 2025 commercialization.

(3d styrofoam wall panels)

FAQS on 3d styrofoam wall panels

Q: How do I install 3D styrofoam wall panels?

A: Clean the wall surface, apply adhesive to the panel's back, and press firmly. Use finishing nails for extra security. Trim edges with a utility knife for a seamless fit.

Q: Are brown 3D wall panels suitable for bathrooms?

A: Yes, moisture-resistant styrofoam panels work well in bathrooms. Ensure proper sealing at joints. Avoid direct water exposure to prolong durability.

Q: Can wavy 3D wall panels be painted?

A: Absolutely. Use acrylic or latex paint for best results. Lightly sand surfaces first to improve adhesion. Avoid oil-based paints to prevent material damage.

Q: Do 3D styrofoam panels damage walls?

A: No, they’re lightweight and adhesive-mounted. Proper removal leaves minimal residue. Repair minor marks easily with spackle or touch-up paint.

Q: Where to use wavy 3D wall panels for maximum impact?

A: Ideal for accent walls in living rooms or bedrooms. Pair with directional lighting to emphasize textures. Avoid cluttered spaces to maintain visual focus.

Recommended Products

Latest News About CHENG CHUANG

-

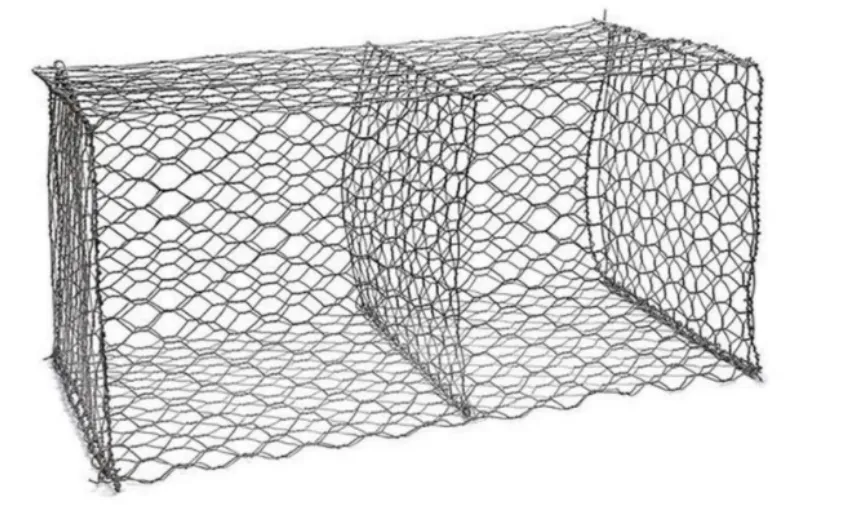

Wire mesh is durableWire mesh represents a cornerstone of modern industrial and agricultural solutions, offering unmatched versatility across countless applications.Read more >

Wire mesh is durableWire mesh represents a cornerstone of modern industrial and agricultural solutions, offering unmatched versatility across countless applications.Read more >Jul 11 2025

-

Safety barrier directs traffic flowIn high-risk environments, safety barrier systems stand as non-negotiable guardians against catastrophic incidents.Read more >

Safety barrier directs traffic flowIn high-risk environments, safety barrier systems stand as non-negotiable guardians against catastrophic incidents.Read more >Jul 11 2025

-

Modular Noise Barrier Eases InstallationUrbanization intensifies noise pollution, making noise barrier systems essential for preserving human health and tranquility.Read more >

Modular Noise Barrier Eases InstallationUrbanization intensifies noise pollution, making noise barrier systems essential for preserving human health and tranquility.Read more >Jul 11 2025

-

Metal fence types enhance securityMetal fence types form the backbone of modern perimeter security solutions worldwide.Read more >

Metal fence types enhance securityMetal fence types form the backbone of modern perimeter security solutions worldwide.Read more >Jul 11 2025

-

Crowd Control Barrier Manages Foot TrafficThe management of public gatherings demands precision, safety, and reliability, making crowd control barrier systems indispensable tools for organizers worldwide.Read more >

Crowd Control Barrier Manages Foot TrafficThe management of public gatherings demands precision, safety, and reliability, making crowd control barrier systems indispensable tools for organizers worldwide.Read more >Jul 11 2025