Types of Metal Fence: Durable & Affordable Options from Top Suppliers

The Indispensable Role and Diverse Applications of Metal Fencing Solutions

In modern infrastructure and agriculture, the strategic deployment of robust fencing solutions is paramount for security, demarcation, and livestock management. Among the various options available, types of metal fence stand out due to their exceptional durability, versatility, and long-term cost-effectiveness. These fences are engineered to withstand harsh environmental conditions, resist corrosion, and provide superior protection compared to traditional wood or plastic alternatives. From safeguarding industrial complexes and public utilities to securing agricultural lands and critical infrastructure, the selection of the appropriate metal fence directly impacts operational efficiency and safety.

The demand for high-performance metal fencing is consistently rising across sectors such as petrochemical, metallurgy, transportation, and agricultural development. Advances in material science and manufacturing processes have led to innovative designs that offer enhanced structural integrity, extended service life, and improved aesthetic integration. Understanding the various classifications and technical specifications is crucial for B2B decision-makers seeking optimal solutions that align with specific project requirements, security protocols, and budgetary constraints. This guide delves into the essential aspects of metal fencing, from manufacturing to application, ensuring a comprehensive overview for discerning buyers.

Understanding the Primary Types of Metal Fence and Their Characteristics

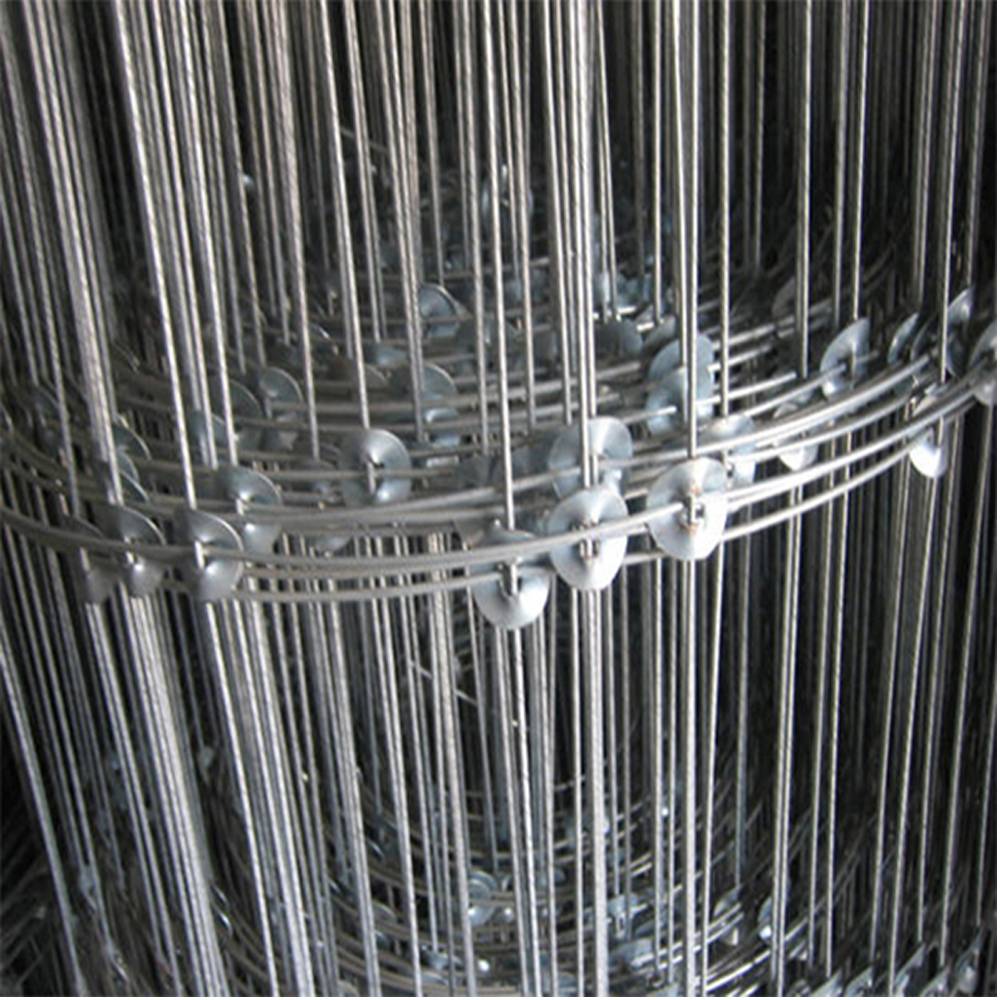

The landscape of metal fencing offers a diverse array of options, each designed for specific applications and performance criteria. Key metal fence types include woven wire fences, welded mesh fences, chain link fences, ornamental fences, and security barricade fences. Woven wire fences, exemplified by our Galvanized Livestock Prevent Hinge Joint Page Wire Farm Field Fence, are particularly favored in agricultural settings for their flexibility and ability to absorb impact from livestock without permanent deformation. These fences typically feature high-tensile steel wire, mechanically woven into a robust grid pattern, often with a "hinge joint" or "fixed knot" design to prevent wire slippage and enhance durability.

Welded mesh fences, on the other hand, consist of steel wires welded at each intersection, providing a rigid and formidable barrier suitable for perimeter security, garden enclosures, and industrial sites. Chain link fences, known for their diamond-shaped mesh, are versatile and cost-effective, widely used for residential, commercial, and temporary event fencing. Ornamental metal fences, often crafted from wrought iron or aluminum, blend security with aesthetic appeal, commonly seen in residential estates and public parks. Each type offers distinct advantages in terms of security level, visual impact, maintenance requirements, and cost, necessitating a careful evaluation based on the intended application.

The Precision Manufacturing Process of Quality Metal Fence Products

The production of high-quality metal fence panels, such as the Galvanized Livestock Prevent Hinge Joint Page Wire Farm Field Fence, involves a multi-stage manufacturing process designed to ensure product integrity and longevity. It begins with the selection of premium raw materials, primarily high-grade carbon steel wire. This wire undergoes a rigorous drawing process to achieve the desired tensile strength and gauge uniformity. Following this, for products like page wire, advanced weaving machinery is employed to form the intricate hinge joint or fixed knot patterns, ensuring that the fence can expand and contract with temperature changes while maintaining structural stability. For welded mesh, automated welding lines precisely fuse the wires at intersections.

A critical step in enhancing durability is surface treatment. Hot-dip galvanization is widely utilized, where the fabricated steel is immersed in molten zinc, creating a metallurgical bond that provides an unparalleled barrier against rust and corrosion. This zinc coating, typically exceeding industry standards like ASTM A116 for farm fencing, significantly extends the fence's service life, often beyond 20-30 years in typical outdoor conditions. Quality control is maintained throughout, with inspections covering wire diameter, mesh spacing, joint strength, and coating thickness, adhering to international standards such as ISO 9001 and ANSI specifications. This meticulous process ensures the final product delivers superior performance in diverse applications, from agricultural to industrial sectors.

Technical Parameters & Performance Benchmarks for Various Metal Fence Types

When evaluating different metal fence types, technical specifications are paramount for making informed procurement decisions. Parameters such as wire gauge, mesh size, tensile strength, coating type, and post requirements collectively define a fence's suitability for specific applications. For agricultural field fences, common wire gauges range from 10 to 14.5 gauge, with higher gauges indicating thinner wire. Mesh spacing varies significantly, influencing the fence’s ability to contain different animals, from small livestock to large game. The hinge joint design, for instance, allows for greater flexibility and impact absorption, making it ideal for containing livestock without injury.

Corrosion resistance is primarily achieved through galvanization, with Class 1, Class 2, and Class 3 coatings indicating increasing zinc thickness and longevity. A Class 3 zinc coating can provide rust protection for well over 20 years in most environments. Tensile strength, measured in pounds per square inch (PSI) or Newtons per square millimeter (N/mm²), determines the wire's resistance to breaking under tension. For high-tensile fences, values often exceed 80,000 PSI, ensuring robust containment. Below is a comparative table detailing common parameters for various metal fence types, offering a quick reference for technical specifications.

Applications Across Industries: Advantages of Robust Metal Fence Solutions

The versatility of metal fence solutions makes them indispensable across a multitude of industries. In the agricultural sector, specifically with products like our Galvanized Livestock Prevent Hinge Joint Page Wire Farm Field Fence, they are critical for effective rotational grazing, protecting crops from wildlife, and ensuring livestock containment. The "hinge joint" design allows for superior flexibility, which is crucial in undulating terrains and for absorbing the impact of large animals, thereby minimizing maintenance and repair costs. This design promotes animal welfare by reducing the risk of injury from rigid barriers, while simultaneously offering excellent long-term value, negating the need for frequent replacements common with less durable materials.

Beyond agriculture, metal fence types serve vital roles in various industrial and public sectors. In petrochemical facilities and metallurgical plants, high-security welded mesh fences or anti-climb designs provide perimeter defense and restrict unauthorized access to hazardous areas, ensuring operational safety and regulatory compliance. For water supply and drainage systems, robust barriers protect critical infrastructure from vandalism and unauthorized tampering. The long life span and minimal maintenance of galvanized fences also translate to significant lifecycle cost savings, which is a key advantage for large-scale industrial projects where durability and reliability are non-negotiable. Furthermore, their inherent resistance to fire, unlike wooden alternatives, adds an extra layer of safety.

Choosing Reliable Metal Fence Suppliers and Custom Solutions

Selecting the right metal fence suppliers is as crucial as choosing the fence itself. A reputable supplier offers not just a product, but a partnership, providing expert advice on material specifications, design options, and installation considerations. Key factors to consider include the supplier's adherence to international quality standards (e.g., ISO 9001), their manufacturing capabilities, and their track record for timely delivery and customer support. Transparency in material sourcing and coating processes, such as certified hot-dip galvanization, ensures the longevity and performance claimed. Leading suppliers also provide detailed technical documentation, including load-bearing capacities and environmental resistance data.

For specialized applications, custom fence solutions are often required. A proficient manufacturer can tailor mesh sizes, wire gauges, heights, and coating types to meet unique project demands, whether it's for specific livestock sizes, extreme environmental conditions, or unusual terrain. For instance, varying post requirements, from treated timber to galvanized steel, can significantly impact the overall fence integrity and lifespan. We collaborate closely with clients to develop bespoke fencing systems that optimize performance and cost-efficiency. Our long-standing expertise in the industry allows us to engineer solutions that not only meet but often exceed project expectations, ensuring seamless integration and durable protection.

Navigating Cost: Finding Value in Cheap Metal Fence Panels Without Compromising Quality

The term "cheap metal fence panels" often evokes concerns about quality, yet cost-effectiveness doesn't have to mean compromising on durability or performance. Smart procurement involves evaluating the total cost of ownership, which includes initial purchase price, installation costs, and long-term maintenance. While some suppliers may offer lower upfront prices by using thinner gauges or inferior coatings, these savings are quickly negated by frequent repairs, shorter lifespan, and potential security breaches. A truly cost-effective solution provides maximum value over its entire service life. For example, a hot-dip galvanized fence, though potentially higher in initial cost, offers superior corrosion resistance and a lifespan that can be five times longer than electro-galvanized alternatives, drastically reducing future expenditure.

To achieve genuine value, focus on suppliers who demonstrate transparency in their material specifications and manufacturing processes. Look for certifications and detailed product data sheets that confirm compliance with industry standards. Volume purchasing, long-term contracts, and exploring standard dimensions rather than highly customized designs can also contribute to more favorable pricing without sacrificing essential attributes. Our approach ensures that even our competitive offerings, such as the Galvanized Livestock Prevent Hinge Joint Page Wire Farm Field Fence, maintain high standards of quality and performance, delivering optimal return on investment for agricultural and industrial clients.

Quality Assurance: Certifications, Testing, and Customer Trust

The credibility of any metal fence manufacturer rests heavily on their commitment to quality assurance. This commitment is often demonstrated through adherence to rigorous international standards and comprehensive testing protocols. For instance, compliance with ISO 9001:2015 for quality management systems signifies a structured approach to production and consistent product quality. Furthermore, specific product standards like ASTM A116 for metallic-coated steel wire woven fence fabric, or ANSI standards for general fencing components, ensure that products meet defined performance criteria for strength, durability, and corrosion resistance. Our products undergo stringent in-house and third-party testing, including salt spray tests for corrosion, tensile strength tests for wire integrity, and impact resistance evaluations, to guarantee their resilience in demanding environments.

Building trust with B2B clients is paramount. This involves not only meeting technical specifications but also providing transparent documentation, reliable customer service, and robust after-sales support. Our long-standing service history and positive client testimonials attest to our dedication to delivering dependable products and solutions. Partnerships with certified raw material suppliers further bolster our authoritative position in the industry. By consistently exceeding industry benchmarks and proactively addressing client needs, we aim to be a preferred choice for all types of metal fence applications, from agricultural to high-security industrial perimeters.

Frequently Asked Questions (FAQ) About Metal Fence Solutions

-

Q: What is the typical lifespan of a galvanized metal fence?

A: Hot-dip galvanized metal fences, especially those with Class 3 zinc coatings, can last for 20 to 50 years or even more, depending on environmental conditions like humidity, salinity, and pH levels in the soil. Proper installation and minimal maintenance further extend this lifespan.

-

Q: Can types of metal fence be customized for specific project needs?

A: Absolutely. Reputable metal fence suppliers offer extensive customization options, including varying heights, wire gauges, mesh configurations, and post types. This allows for tailored solutions for unique terrains, security requirements, or livestock containment challenges.

-

Q: What is the delivery time frame for large orders of metal fence panels?

A: Delivery schedules vary based on order volume, product type, and current production capacity. Typically, for standard orders, lead times range from 2 to 4 weeks. For large or custom orders, a detailed production and delivery schedule will be provided upon consultation, ensuring transparency and efficient logistics planning.

-

Q: What kind of warranty do you offer on your metal fence products?

A: We stand by the quality of our products. Our galvanized metal fences typically come with a comprehensive warranty covering material defects and coating performance for up to 10-20 years, depending on the product line and specific application. Full warranty details are provided with each quotation and purchase agreement.

-

Q: What after-sales support is available?

A: Our commitment extends beyond delivery. We offer technical support for installation queries, maintenance advice, and troubleshooting. Our dedicated customer service team is available to assist with any concerns post-purchase, ensuring your long-term satisfaction with our metal fence solutions.

Conclusion: Investing in Superior Metal Fence Solutions

The strategic selection and deployment of the right metal fence system is a critical investment for any industrial, commercial, or agricultural enterprise. From the robust Galvanized Livestock Prevent Hinge Joint Page Wire Farm Field Fence to high-security welded mesh systems, understanding the diverse types of metal fence and their specific attributes is key to optimizing functionality, enhancing safety, and ensuring long-term value. Emphasizing quality materials, advanced manufacturing processes like hot-dip galvanization, and adherence to international standards are paramount for durability and corrosion resistance.

Choosing experienced metal fence suppliers who offer comprehensive technical support, customization capabilities, and a strong commitment to quality assurance will safeguard your investment. While the concept of "cheap metal fence panels" may tempt some, prioritizing the total cost of ownership, which includes longevity and minimal maintenance, ultimately yields superior returns. Our dedication to providing high-performance, reliable, and cost-effective metal fencing solutions ensures that clients receive products that stand the test of time and meet the most demanding operational requirements.

References

- ASTM A116-20, Standard Specification for Metallic-Coated Steel Wire Woven Fence Fabric.

- International Organization for Standardization (ISO) 9001:2015, Quality management systems – Requirements.

- National Association of Corrosion Engineers (NACE) International, "Corrosion Costs and Preventive Strategies in the United States".

- Agricultural Extension Programs on Livestock Management and Fencing Best Practices.

Recommended Products

Latest News About CHENG CHUANG

-

Wire mesh is durableWire mesh represents a cornerstone of modern industrial and agricultural solutions, offering unmatched versatility across countless applications.Read more >

Wire mesh is durableWire mesh represents a cornerstone of modern industrial and agricultural solutions, offering unmatched versatility across countless applications.Read more >Jul 11 2025

-

Safety barrier directs traffic flowIn high-risk environments, safety barrier systems stand as non-negotiable guardians against catastrophic incidents.Read more >

Safety barrier directs traffic flowIn high-risk environments, safety barrier systems stand as non-negotiable guardians against catastrophic incidents.Read more >Jul 11 2025

-

Modular Noise Barrier Eases InstallationUrbanization intensifies noise pollution, making noise barrier systems essential for preserving human health and tranquility.Read more >

Modular Noise Barrier Eases InstallationUrbanization intensifies noise pollution, making noise barrier systems essential for preserving human health and tranquility.Read more >Jul 11 2025

-

Metal fence types enhance securityMetal fence types form the backbone of modern perimeter security solutions worldwide.Read more >

Metal fence types enhance securityMetal fence types form the backbone of modern perimeter security solutions worldwide.Read more >Jul 11 2025

-

Crowd Control Barrier Manages Foot TrafficThe management of public gatherings demands precision, safety, and reliability, making crowd control barrier systems indispensable tools for organizers worldwide.Read more >

Crowd Control Barrier Manages Foot TrafficThe management of public gatherings demands precision, safety, and reliability, making crowd control barrier systems indispensable tools for organizers worldwide.Read more >Jul 11 2025